A Study on Improvement in Achieving The Production Plan vs Actual of Machine Shop by Analysing The Overall Equipment Efficiency at Tata Advance System Limited Nagpur

Main Article Content

Abstract

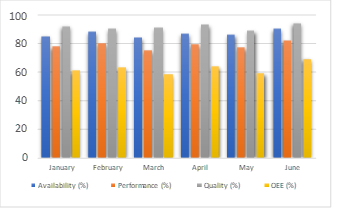

Achieving alignment between planned production targets and actual output is a critical challenge in manufacturing industries. This study focuses on analysing production deviations in the machine shop at Tata Advanced Systems Limited, Nagpur, using Overall Equipment Efficiency (OEE) as a key performance metric. OEE is a widely used standard for evaluating machine shop performance, incorporating three primary components: availability, performance, and quality. A lower-than-expected OEE often results in production inefficiencies, impacting operational effectiveness and delivery schedules. The research identifies major factors contributing to production deviations, including unplanned machine downtime, reduced operating speed, and defective output. Using data-driven methods such as OEE calculations, Pareto analysis, and Root Cause Analysis (RCA), the study evaluates the impact of inefficiencies on production output. Findings indicate that machine downtime, operator inefficiencies, and material flow disruptions are significant contributors to performance gaps. To bridge these gaps, the study proposes key strategies such as predictive maintenance, workforce skill enhancement, process standardization, and real-time monitoring systems. Implementing these measures can optimize machine utilization, improve workforce efficiency, and ensure better alignment between planned and actual production targets. This research provides valuable insights for manufacturing managers and decision-makers seeking to improve production efficiency and machine shop performance. Future studies can explore AI-based predictive analytics and automation techniques to further enhance productivity and operational control. The findings of this study contribute to continuous improvement methodologies aimed at increasing overall manufacturing efficiency and competitiveness in the industry.

Downloads

Article Details

This work is licensed under a Creative Commons Attribution-NoDerivatives 4.0 International License.