Minimize Print Mottle by Optimizing Process Parameters in Offset Print

Main Article Content

Abstract

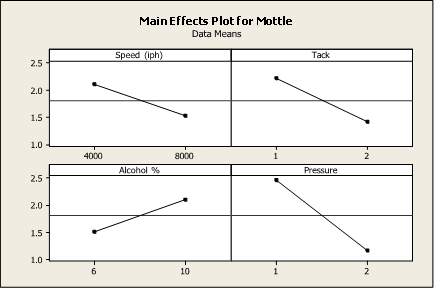

The offset printing technology is extensively utilized in packaging and commercial printing for both short and large production runs. The offset printing process is a multifaceted technique that encompasses the printing machine, substrate, ink, and their interaction. The offset printing process involves the greatest number of variables compared to all other printing methods. The minor fluctuation in process parameters causes in variations in ink transfer, leading to unequal outcomes. This results in variations in color and gloss on the printed surface, referred to as print mottle. Therefore, it is essential to comprehend and regulate the process parameters to achieve high-quality printing while minimizing mottle. The study aims to investigate the impact of key elements, including ink tack, alcohol percentage, press speed, and impression pressure, on print mottle. The color variance is assessed by differences in ink transfer, which is influenced by print mottle. The IA Print Target Software has been utilized to assess print mottle. Production runs have been executed on the press to establish a baseline for print defects, and a target has been established to minimize them. A comprehensive full factorial design of experiments has been established for the aforementioned process parameters at two levels. The experimental data has been evaluated using ANOVA and Main and Interaction plots to identify the ideal combination that produces high-quality prints with reduced print mottle. The optimized configuration demonstrated a 65% decrease in solid mottle.

Downloads

Article Details

This work is licensed under a Creative Commons Attribution-NoDerivatives 4.0 International License.