Design & improvement in hydraulic Side broom to Pneumatic side broom used in Mechanical Sweeper machines

Main Article Content

Abstract

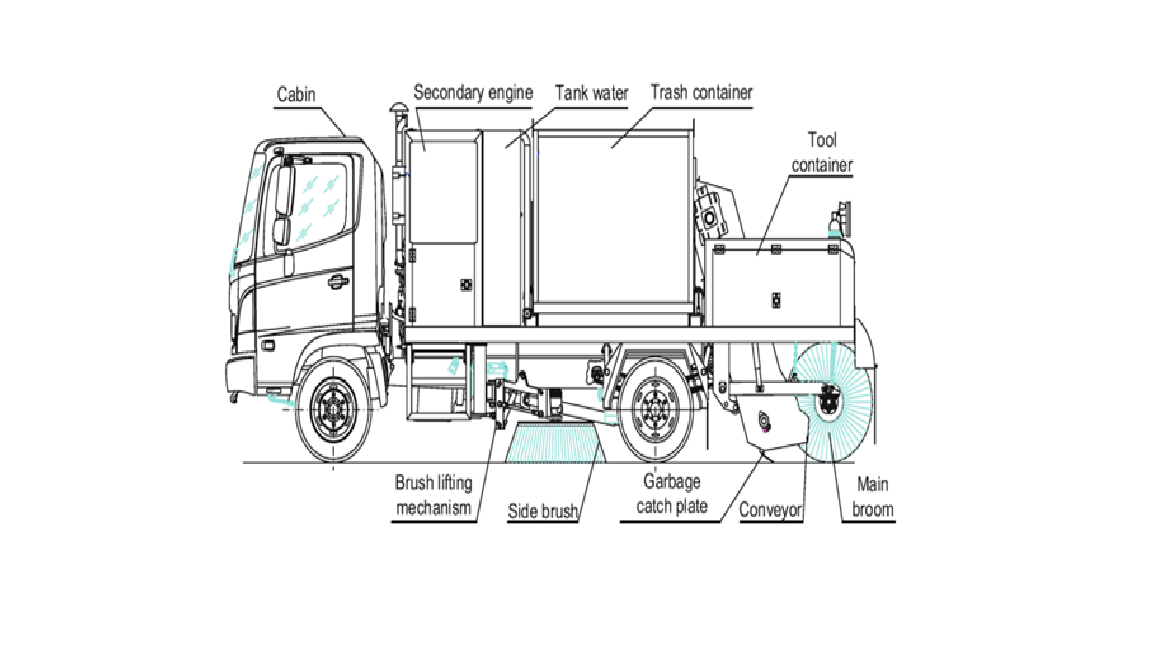

The transition from hydraulic to pneumatic side brooms in mechanical sweeper machines represents a significant advancement in street cleaning technology. Hydraulic side brooms, traditionally powered by hydraulic pumps and fluid systems, often face issues such as complexity, maintenance challenges, high energy consumption, and environmental concerns due to potential fluid leaks. This paper explores the design improvements and benefits of replacing hydraulic systems with pneumatic side brooms, which use compressed air for actuation and control. Pneumatic systems offer a simpler, more efficient alternative by reducing the number of components, lowering maintenance costs, and enhancing energy efficiency. Pneumatic side brooms also provide greater flexibility in adjusting broom height, angle, and rotation speed, improving overall performance. The design considerations for pneumatic systems include air compressor capacity, optimized air delivery systems, durable pneumatic cylinders, and enhanced safety features. Furthermore, integrating advanced control systems can further improve the precision and adaptability of pneumatic side brooms. The paper highlights the environmental advantages, reduced operational costs, and improved reliability of pneumatic systems, positioning them as a promising solution for modernizing mechanical sweepers. This transition not only enhances the operational capabilities of sweepers but also contributes to sustainability and operational efficiency in municipal and industrial street cleaning.

Downloads

Article Details

This work is licensed under a Creative Commons Attribution-NoDerivatives 4.0 International License.