Arduino-Based Automated Box Sorting and Tracking System

Main Article Content

Abstract

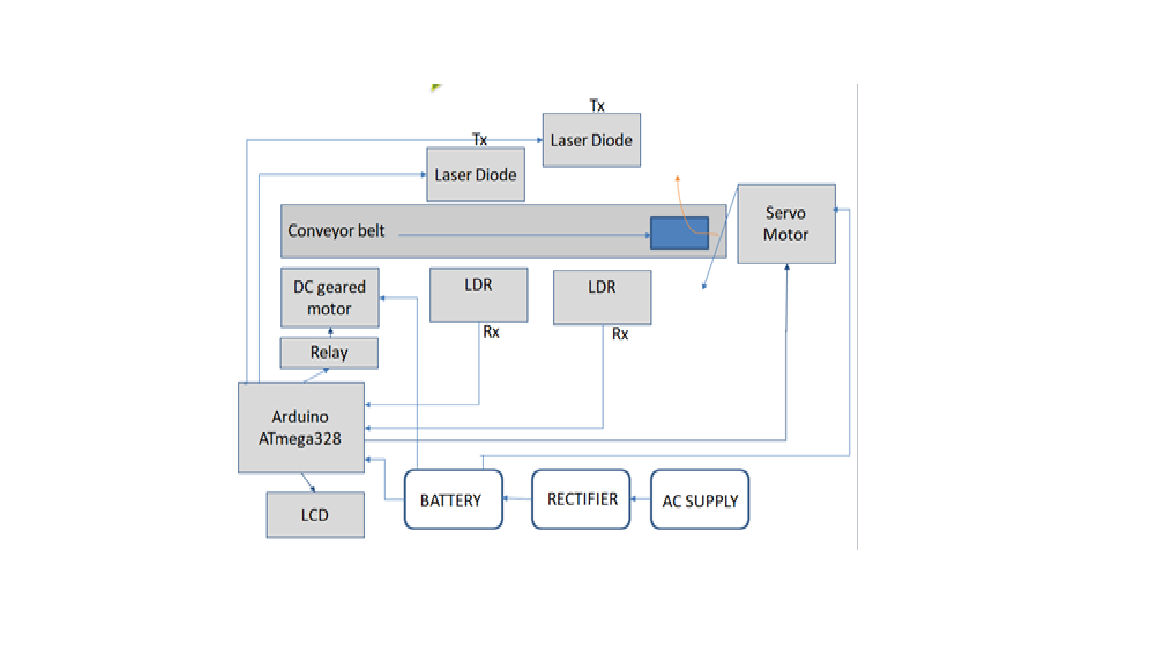

The creation of a box sorting system based on size represents a significant improvement in mechanical automation, aimed at optimizing the sorting process and boosting overall efficiency. This system combines modern sensors, controllers, and actuators to reduce manual labor and minimize errors. It tackles key supply chain issues by incorporating transport systems for smooth movement of boxes, detection sensors to identify items, and a measurement system using lasers or infrared sensors for accurate size readings. These elements work together to ensure correct sorting decisions, with a Programmable Logic Controller (PLC) processing data from the sensors to guide the sorting. The sorting mechanism relies on pneumatic cylinders, solenoids, or servo motors to direct boxes into appropriate chutes or pathways according to their size. A Human-Machine Interface (HMI) enables operators to monitor and manage the sorting process in real-time. A reliable communication system ensures smooth data transfer between the system's components, facilitating coordination and efficient operation. The design prioritizes safety, incorporating emergency tools, security sensors, and input systems to prevent accidents and maintain sorting accuracy. Extensive testing is carried out to assess factors such transport speed, compatibility with different box sizes, and overall sorting precision. The system's design also supports easy maintenance and adaptability, making it well-suited to meet the changing needs of industries that rely on effective box sorting. Ultimately, this system enhances precision, dependability, and efficiency in supply chain management, improving the sorting process and fostering better interdepartmental coordination.